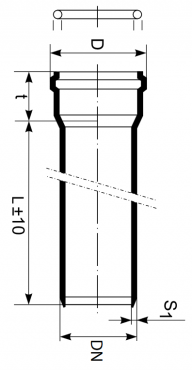

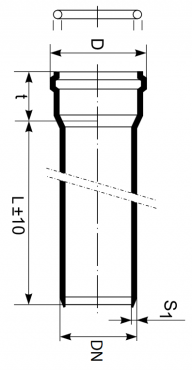

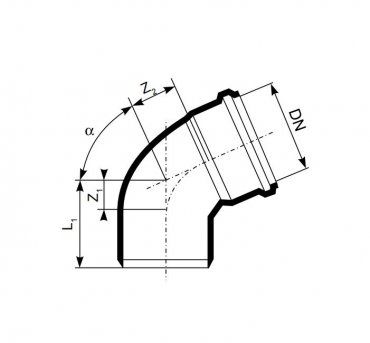

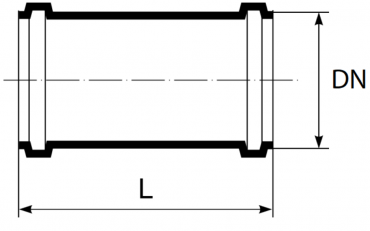

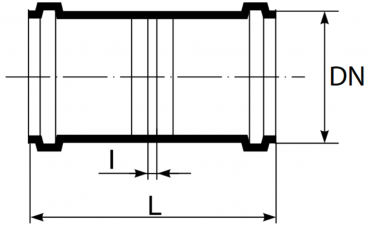

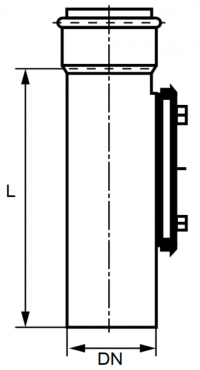

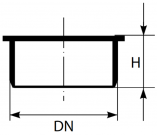

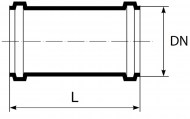

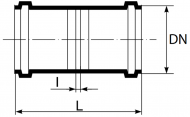

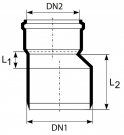

KG 2000 SN10 and SN16 is a modern, high-performance solid pipe system for the construction of sanitary and rainwater drainage systems. Even under extreme loads, it remains tight, safe and economical for at least 100 years. It can be supplied in all standard sizes from DN 110 to DN 500.

Application

The KG 2000 SN10 and SN16 pipe and fitting system can be used in the following application areas:

Main installation

duct to be connected

In addition, it is successfully used in heavy-duty areas (SLW 60) with a minimum cover of 0.8 m and a maximum cover of 6 m and in groundwater areas.

KG 2000 pipes and fittings can be directly concreted, taking into account the manufacturer's instructions.

KG 2000 can be laid on even, relatively loose, fine-grained substrates when they allow the pipes to be supported over their entire length.

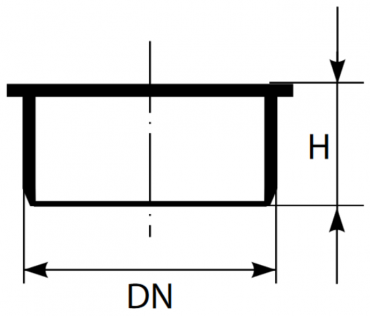

The special, patented, triple seal used in the KG 2000 system fulfils a number of important functions:

retaining edge - causes the lip seal to be pressed against the pipe edge and prevents the sealing ring from slipping down or collapsing

scraping edge - used to eliminate impurities on the pipe.

Sealing ring - seals the pipe connection permanently. Firstly, it ensures that no sewage enters the groundwater (penetration) and secondly, that groundwater does not enter the pipeline network (soakage). The leak test of pipes according to DIN EN 1610 is carried out with air and water at a pressure of 0.05 bar to 0.5 bar and in a vacuum.

The KG 2000 SN10 and SN16 system is also suitable for installation in the drinking water zone ll. Adequate testing of the system according to ATV A 142 at 2.4 bar has been confirmed by MPA Darmstadt.